In 2000, Sandy Lawton and his business partner, Adam Lougee, had developed a beautiful piece of woodland and fields with rugged ledge outcrops into 10 house lots with shared community space, conserved land, and trails that has today become the main entrance to one of the most beautiful and interesting town forests which overlooks the Mad River. This rugged beauty has inspired him to develop a unique structural language in concrete using geotextile fabric as his formwork. In 2006, Sandy Lawton of ArroDesign, a design-build company in Waitsfield, Vt began to focus on constructing more durable, energy-efficient houses in the Mad River Valley.

In 2016, he was asked to design and construct a 1000 square foot house using fabric cast concrete for a school teacher who wanted a small cabin in the woods.

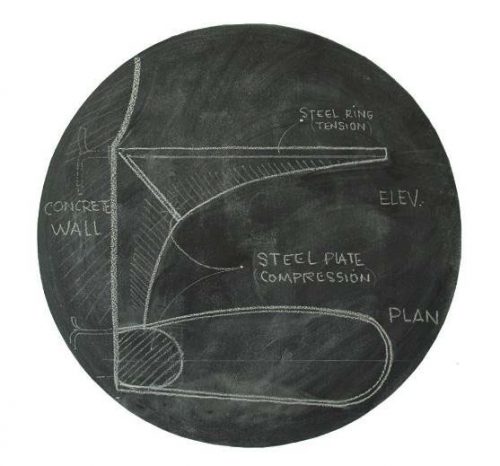

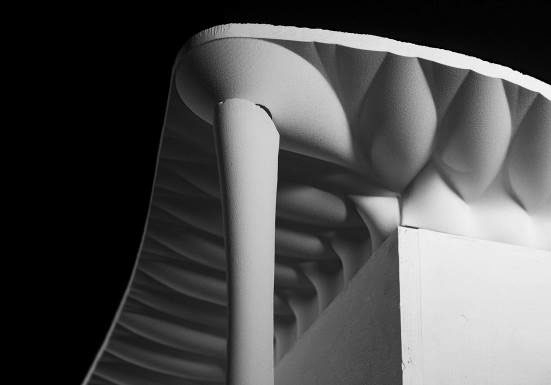

These benefits of using fabric cast concrete include optimization of the structure of the building as well as the development of an ornamental language unique to fabric formed concrete. The genesis of architectural ornament derives in part from ritual and a human instinct for imitation. Early architectural ‘enclosures’ were the first plant fiber woven mats and then woven tapestries. The use of tapestry in ritual and ceremony were memorialized and transformed as decorative and structural motifs in wall architecture and building facades. The house integrates technical aspects of casting with fabric with the rituals of modern-day living and residential design. Wall and façade elements simultaneously support the building, mediate between the exterior and interior spaces, and provide a rich sculptural backdrop that envelops human activity.

A cantilevered porch surrounds the living room and kitchen, providing shade in the summer and a sheltered entrance in the winter. A large second story terrace creates a private outdoor living room that was inspired by the naturally occurring elevated plains. The second floor supports a roof garden. The exterior concrete formwork pattern is designed to have similar qualities with the surrounding forest and ledge outcroppings.

A small vaulted ceiling is incorporated around cantilevered concrete stair to take advantage of western exposure and let warm air escape during the summer months, creating natural ventilation. In the winter, the stair acts as a Trombe wall. This central concrete interior wall can heat up in the winter as a heat sink and help modulate the interior temperature of the living area.

Climate Resilient Buildings with Composite Structures

Eleanor H. D’Aponte • Sandy Lawton,

Ronnie Araya

*Norwich University

Vermont, USA

edapont@norwich.edu

a,b ArroDesign

Montreal, Canada

Waitsfield, Vermont

Abstract

This paper examines the issues associated with constructing a climate-resilient building that combines the latest technical innovations in concrete casting with a traditional frame construction to produce an energy-efficient, durable structure that has a much higher degree of resiliency to withstand the ongoing weather impacts of climate change. This new composite structure, with its durable exoskeleton, can be designed and engineered to withstand high wind events such as hurricanes and tornadoes, forest fires, floods, and to a high degree, earthquakes. Its durability also has the advantage of increasing the longevity of the structure and minimizing long term maintenance. The process is somewhat different than the current standard concrete construction. However, it is designed to use common construction techniques. In this way, it is adaptable to both residential and commercial construction.

The flexibility in form making challenges traditional design and construction processes including the level of resolution in the design, the control of parameters and casting conditions, and the connectivity of building systems. Three case studies in North America: a 1,970 sq. ft. fabric formed concrete residence built in 2009, a 1,800 sq. ft. prototypical passive house, and a 1100 sq. ft. residence constructed in 2017 based on the prototype will be explored. Issues such as constructability, scheduling, and reduced formwork waste will be addressed. Composite structures, which combine both fabric formed concrete and conventional framing methods, will be explored.

arro design

4199 Main Street Waitsfield Vermont 05673 | 802-496-3234 | arrodesign@gmail.com | www.arrodesign.org